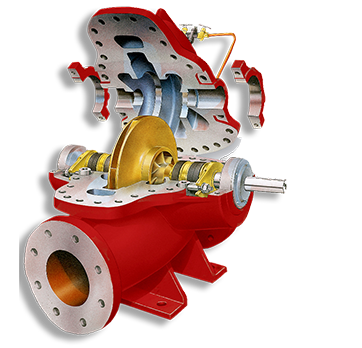

Patterson End Suction Pumps handle water and clear industrial fluids at flows to 2,500 GPM and heads to 400 ft. TDH. They feature a high-efficiency design that minimizes energy consumption, and their back pullout configuration, including a sliding motor base, provides easy access for maintenance without disturbing piping connections. Every pump is hydrostatically pressure-tested to 1-1/2 times shutoff before shipment.

These pumps are engineered to last, with a precision cast, dynamically balanced impeller that minimizes vibration and maximizes bearing life. Precision bearings and machining limit shaft deflection. Other long-life features include registered fits at the volute cover for precise alignment, machined mounting surfaces and integrally cast packing boxes, casing rings, grease-lubricated bearings and a carbon mechanical seal (tungsten carbide optional), positively lubricated. A fitted bronze shaft sleeve and a self-flushing mechanical seal protects the shaft. Two end suction models are available—frame-mounted and close-coupled. Closed-coupled units can be either flanged or threaded.